In hochmodernen Branchen wie der Luft- und Raumfahrt, dem Bootssport oder der Industrie, in denen es auf jeden Leistungszuwachs ankommt, müssen Materialien Leichtigkeit, Effizienz und einfache Verarbeitung vereinen.

Im Mittelpunkt dieser Revolution steht eine Technologie, die heraussticht: Towpreg, ein unidirektionales Prepreg, das für automatisierte Fertigungsprozesse wie Filament Winding oder Fiber Placement (AFP) entwickelt wurde.

Um den wachsenden Anforderungen von Ingenieuren, Konstruktionsbüros und Industriellen gerecht zu werden, hat Toray Carbon Fibers Europe eine Reihe fortschrittlicher Towpregs entwickelt, die eine sehr hohe Breitenkontrolle, eine gleichbleibende Imprägnierrate und Anpassungsfähigkeit an die anspruchsvollsten industriellen Anwendungen kombinieren.

Gebrauchsfertige Towpreg-Rolle

Ich kontaktiere Toray Carbon Fibers Europe

Towpreg und seine Rolle in fortschrittlichen Verbundwerkstoffen verstehen

Was ist ein Towpreg?

Towpreg, eine Kontraktion aus Tow (Faserstrang) und Prepreg (Pre–impregniertes Material), bezeichnet einen durchgängig mit Harz imprägnierten Endlosfaserstrang, der direkt in automatisierten Fertigungsverfahren für Verbundbauteile eingesetzt werden kann. Die Fasern bestehen in der Regel aus Carbon und das Harz – thermoplastisch oder duroplastisch – wird nach einem kontrollierten Prozess aufgetragen, um eine homogene Verteilung und einen konstanten Harzgehalt zu gewährleisten.

Im Gegensatz zu Prepreg-Lagen, die zur Erzeugung von Spaltbändern geschnitten werden müssen, wird Towpreg direkt in der richtigen Breite hergestellt. Es bietet somit mehrere entscheidende Vorteile:

- Eine 100%ige Endlosfaser ohne Schnittkanten, um ihre mechanischen Eigenschaften voll auszuschöpfen

- Das Fehlen von Spleißen, was eine Materialeinsparung bei der Konstruktion ermöglicht,

- Lange Rollen, wodurch Produktionsunterbrechungen reduziert werden.

Eine ideale Antwort auf die Herausforderungen der Hochleistungs-Composite-Industrie.

Konventionelles Towpreg vs. Advanced Towpreg: Was sind die Unterschiede?

Der Advanced Towpreg von Toray Carbon Fibers Europe übertrifft die Grenzen herkömmlicher Prepreg-Bits. Wo herkömmliche Towpregs Unregelmäßigkeiten beim Harzauftrag, Haftungsprobleme oder Breitenschwankungen aufweisen, bietet Toray Carbon Fibers Europe eine kontrollierte und bewährte Lösung.

Was ändert sich mit dem Advanced Towpreg Toray:

- Hohe Breitenstabilität: Die Breite wird bereits bei der Herstellung festgelegt – ganz ohne Zuschnitt – und ist optimal auf AFP-Anlagen abgestimmt.

- Gleichmäßige Imprägnierung: dies ermöglicht eine präzise Konstruktion und hohe Wiederholbarkeit der hergestellten Verbundbauteile.

- Große Auswahl an Harzsystemen: je nach Anwendung und Kundenwunsch können verschieden Harzsysteme ausgewählt werden – darunter auch niedrig-klebende Formulierungen, die den Einsatz von Trennfolien überflüssig machen.

- Vollständige Kontrolle des Prozesses: von der Faserherstellung bis zur Imprägnierung, so dass wir dank.

Eine erfolgreiche Lösung, die für anspruchsvolle Industrieumgebungen und komplexe Spezifikationen entwickelt wurde.

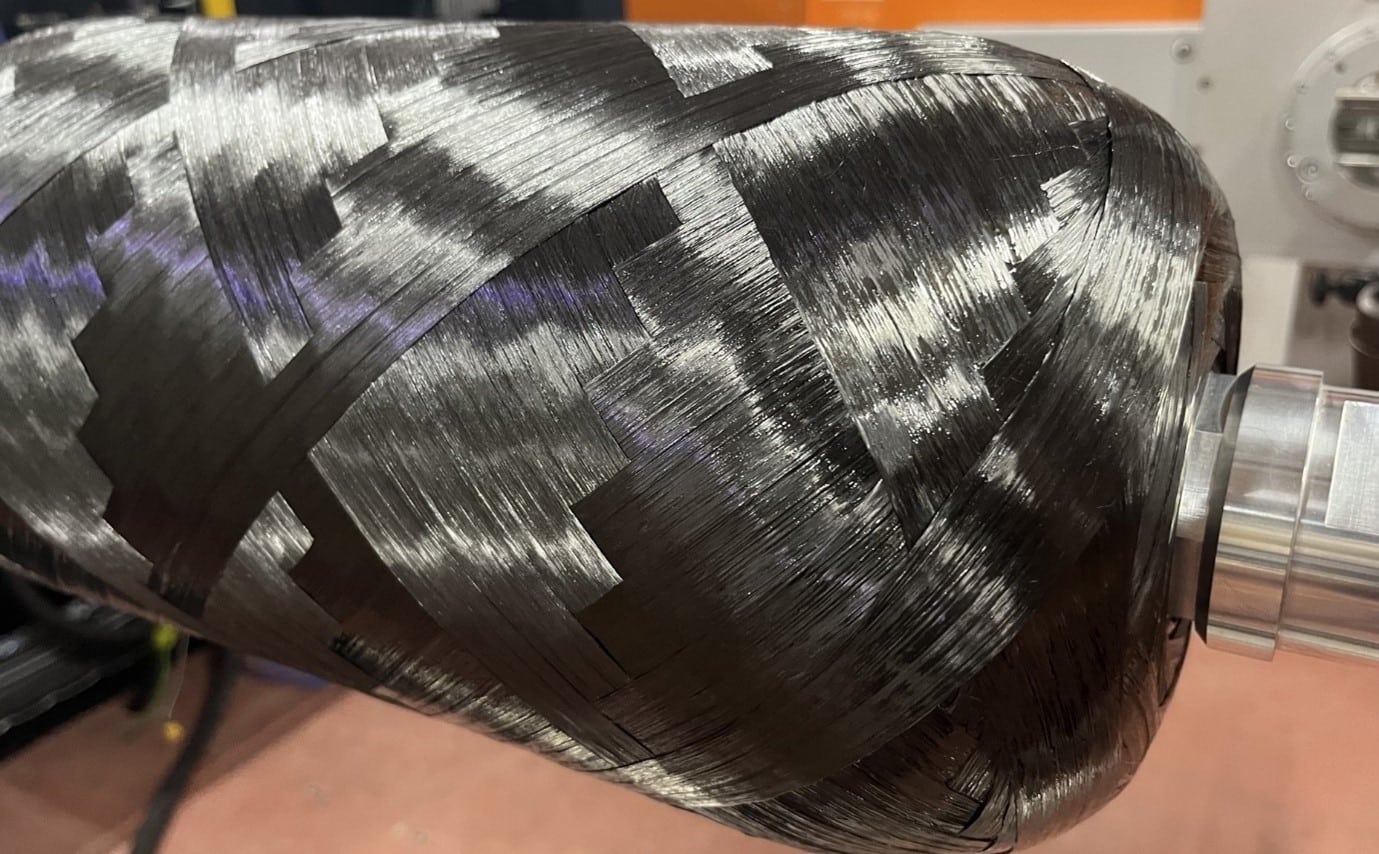

Filament Winding, Towpreg Deposit auf einem Typ IV Tank

Bewährte Leistung in den anspruchsvollsten Branchen

Der Advanced Towpreg wird in Frankreich und Europa bereits von Herstellern verwendet, die in der Luft- und Raumfahrt sowie im Bootssport tätig sind, wo die geringste Abweichung in Bezug auf Gewicht oder Steifigkeit die Rennleistung beeinträchtigen kann und wo die Zuverlässigkeit der Materialien unter anspruchsvollsten Bedingungen getestet wird.

AFP-Drapierung einer Folie im „Out-of-Plane“-Verfahren bei Avel Robotics mit einem Towpreg unter Verwendung von TORAYCA-Fasern von Toray Carbon Fibers Europe

Im letzten Teil stehen die Hydrofoils des MACIF-Bootes stellvertretend für den erfolgreichen Einsatz von Advanced Towpreg im Fokus. Der von AVEL Robotics in Lorient entworfene Foilaufbau nutzt das Advanced Towpreg von Toray Carbon Fibers Europe: Diese Unterwasserflügel ermöglichen es dem Boot, über dem Wasser zu „fliegen“ und so an Geschwindigkeit zu gewinnen.

In diesem extremen Kontext, in dem jedes Gramm zählt und die Ermüdungsbeständigkeit entscheidend ist, lag die Wahl von Toray Towpreg nahe. Heute werden alle von Avel Robotics produzierten IMOCA-Foils mit Advanced Towpreg gefertigt. Das Ergebnis: leistungsstärkere Teile, optimierte Materialnutzung, Zeitersparnis in der Produktion und nachgewiesene Zuverlässigkeit unter realen Segelbedingungen.

Dieses Projekt veranschaulicht perfekt die industrielle Reife des Produkts und seine Fähigkeit, sowohl auf Wasser als auch auf der Erde und in der Luft komplexe und ehrgeizige Spezifikationen zu erfüllen.

Charlie Dalins Sieg an Bord seines Foiling-Imoca MACIF, gebaut mit Advanced Towpreg von Toray Carbon Fibers Europe, am 14. Januar 2025 in Les Sables d’Olonne nach seiner Weltumsegelung (Vendée Globe). Abbildung: MACIF Jean-Louis Carli, Vincent Curutchet

Warum sollten Sie sich für Toray Carbon Fibers Europe für Ihre Verbundwerkstoffprojekte entscheiden?

Vollständige Kontrolle der Wertschöpfungskette

Was Toray Carbon Fibers Europe auszeichnet, ist neben der Produktleistung auch die vollständige Kontrolle des industriellen Prozesses:

- Torayca-Fasern®, die im eigenen Haus hergestellt und kontrolliert werden,

- Hochleistungsharze, maßgeschneidert von den R&D-Teams von Toray Carbon Fibers Europe für höchste Performance.

- Französische Produktion, für Rückverfolgbarkeit, Versorgungssicherheit und Reaktionsfähigkeit, um die genaueste Unterstützung für Projektpläne zu bieten,

- Ein engagiertes technisches Team, das die Bedürfnisse erfüllt und gemeinsam Lösungen entwickelt, die auf Ihre spezifischen Bedürfnisse zugeschnitten sind.

Eine Garantie für Qualität, Reaktionsfähigkeit und Rückverfolgbarkeit bei jeder Bestellung.

Know-how im Dienste Ihrer Spezifikationen

Jedes Projekt ist einzigartig. Toray Carbon Fibers Europe unterstützt seine Kunden mit einem kollaborativen Ansatz:

- Technische Diagnose und persönliche Unterstützung,

- Materialempfehlung entsprechend Ihrer Prozesse,

- Unterstützung der Industrialisierung auf der AFP-Leitung oder -Wicklung,

- Lückenlose Dokumentation und garantierte Rückverfolgbarkeit

Um mehr zu erfahren oder Ihr Projekt zu besprechen, wenden Sie sich an die Teams von Toray Carbon Fibers Europe oder fordern Sie unsere technische Dokumentation an.

Ich kontaktiere Toray Carbon Fibers Europe