Epsilon Composite, a global leader in carbon fiber pultrusion, and Toray Carbon Fibers Europe, a subsidiary of Toray Industries and the world’s leading carbon fiber manufacturer, have been working together for 15 years to promote the use of carbon fiber in electrical infrastructure. Our composite core cables are designed to modernize and reinforce high-voltage power lines.

This collaboration has culminated in numerous projects worldwide and a major framework agreement recently signed in the Netherlands.

An Innovative Technology Essential for Modernizing Power Grids

Since the qualification of Epsilon Composite’s HVCRC® technology in 2010, which incorporates Torayca® carbon fiber, the two French companies have played a key role in modernizing and strengthening power grids globally.

HVCRC® conductor, composed of a structural composite core made from carbon fiber

Thanks to the light weight, strength, and exceptional thermal stability of carbon fiber, HVCRC® cables can effectively replace traditional metal cables, which are based on technology from the early 20th century. These cables can double the capacity of existing power lines quickly and cost-effectively. In contrast, building new traditional lines typically takes over a decade and requires significant investment, often at the expense of the environment and landscape.

Increasing transmission capacity is essential to meet the growing global demand for electricity and to connect new renewable energy sources (such as solar and wind) in support of decarbonization efforts. These advanced cables also offer numerous benefits, including a 30% reduction in electrical losses, enhanced grid resilience to extreme weather events, and a reduced risk of wildfires.

Today, this technology is recognized worldwide as a benchmark for modernizing transmission and distribution lines, with several thousand kilometers of cables installed across Asia-Pacific, Africa, Europe, and the Americas.

With composite core conductors increasingly adopted by European grid operators, Epsilon Composite’s technology has recently been selected for several major contracts in Europe, ensuring a sustained industrial activity for years to come.

Framework Agreement Signed for Modernizing the Dutch High Voltage Grid

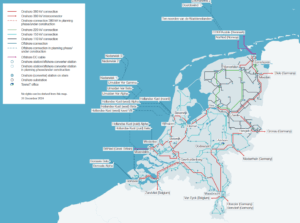

Like many European grid operators, TenneT (Netherlands) recently selected the HVCRC® technology through a framework agreement to modernize the whole Dutch 400 kV high voltage grid until 2030.

Map of the Dutch electricity grid, managed by TenneT

Following a tender launched in 2024, TenneT selected two European cable manufacturers partnered with Epsilon Composite —Nexans and DeAngeli Prodotti— to produce HVCRC® conductors.

For this tender, the Dutch grid operator challenged suppliers to optimize not only their products but also their supply chains and operations to minimize electrical losses and greenhouse gas emissions throughout the product lifecycle. TenneT also required a life cycle analysis to assess the environmental impact of the products, integrating this data into the evaluation process.

Epsilon Composite’s proactive efforts over the years to assess and optimize the environmental impact of its production and supply chain contributed significantly to this process.

Implementation of the framework agreement has already begun, with two pilot projects underway to qualify HVCRC® cables manufactured by Nexans and DeAngeli Prodotti, as well as Epsilon’s Corecheck® technology, which ensures the integrity of the composite core at every stage of manufacturing and installation.

The project is expected to continue until all remaining metallic conductors on TenneT’s 400kV lines are replaced.

Composite Core Conductors: An Industrial Success Story from France

This industrial success highlights the excellence of a pioneering and export-oriented French sector, firmly rooted in France and Nouvelle-Aquitaine region, known for its proactive industrial policies.

In Lacq (Pyrénées-Atlantiques), Toray Carbon Fibers Europe operates one of the world’s largest carbon fiber production plants, while Epsilon Composite, a family-owned company founded in 1987, is headquartered in Gaillan-en-Médoc (near Bordeaux), where it manufactures all its products.

Composite core manufacturing in Epsilon Composite’s pultrusion workshop

Both companies continue to invest in R&D and production capacities to support market growth. Toray Carbon Fibers Europe is completing the construction of a sixth carbon fiber production line, set to be operational by the end of 2025. This new carbon fiber line will further strengthen the company’s position as the leading supplier of the European market and guarantee a national supply of this strategic material.

Torayca Carbon Fiber Bobbins

“After 40 years of collaboration, including 15 years on composite cores, Epsilon Composite and Toray CFE demonstrate the strength of a long-standing, innovative and effective industrial partnership, placing the composites sector at the heart of the global energy transition challenge.

This industrial cooperation between two industry leaders is fully aligned with the objectives of decarbonizing the economy and strengthening electrical infrastructure.”

Alexandre LULL, Deputy CEO of Epsilon Composite

“We are delighted with the new contract signed by Epsilon for the Dutch market. As a partner, Toray Carbon Fibers Europe guarantees the supply of Torayca® carbon fiber for this long-term project. We are convinced that this innovative HVCRC® technology is contributing to the future of electrification in the European and global markets.”

Armin KLESING, Marketing and Sales Director at Toray Carbon Fibers Europe