Weight reduction, improved performance, lower emissions: carbon fiber is redefining the standards of the aviation industry. Whether commercial jets, civilian drones, military aircraft, or the next generation of eVTOLs, composite materials are driving the sector’s most ambitious innovations.

Dassault Rafale fighter jet in flight

For over four decades, Toray Carbon Fibers Europe has been at the forefront of this transformation. Our expertise in high-performance fibers and our fully integrated industrial ecosystem enable us to support both global leaders like Airbus and Boeing, as well as emerging players in air mobility (UAVs, flying taxis, etc.).

Our mission? To help you design aircraft that are lighter, stronger, and more efficient.

Contact Toray Carbon Fibers Europe

Why Is Carbon Fiber a Game-Changer in Aeronautics?

Aeronautics is one of the most demanding industries on the planet. Materials must endure repeated high cyclic loads (takeoff, cruising, landing), resist vibrations, and withstand extreme temperatures, while maintaining structural integrity over a service life that can exceed 30 years.

Carbon fiber based composites stand out for their exceptional properties:

- Up to 50% weight reduction compared to metals, without compromising on rigidity;

- Superior mechanical performance: tensile strength, fatigue resistance, impact resistance, and thermal stress

- Enhanced durability: better corrosion resistance, minimal aging, and reliable performance in extreme conditions

- Fuel efficiency optimization: lower fuel consumption, more freedom in airfoil designs, extended range, reduced CO₂ emissions, and quieter operation

These advantages make carbon fiber a strategic tool to improve performance of primary structures (fuselages, wings, empennages) and advanced applications (turbojets, high-lift flaps, mechanical parts, tanks, interiors).

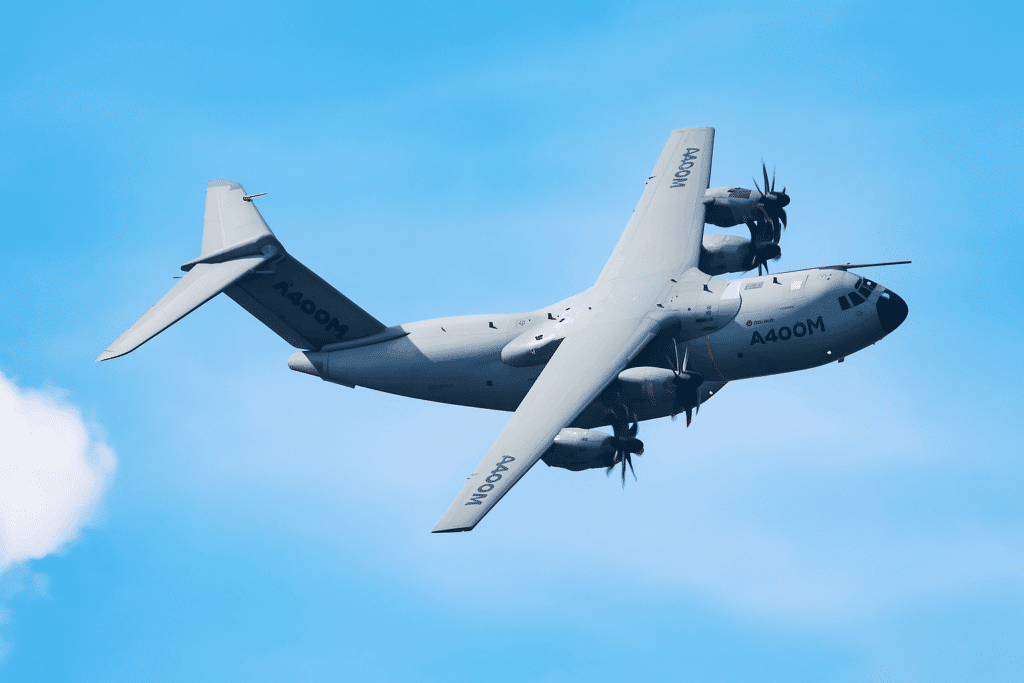

Airbus A400M aircraft in flight

Machining, Performance, and Certification: Toray’s Expertise

High-Performance Fibers for Aeronautical Programs

Toray Carbon Fibers Europe has been manufacturing aerospace-grade carbon fibers for over 40 years. Our portfolio includes some of the most widely-used fibers in the European market:

| Fiber Type | Applications | Key Performance |

| T300 | Secondary structures, interior, defence | High quality and excellent processability |

| T700G | Primary and secondary structures, interior, defence | Enhanced adhesion properties for a high-strength fiber |

| T800H | Primary structures: fuselage, wings, empennages (commercial & military aviation), Defence | Excellent strength-to-stiffness ratio |

| T800S | Primary structures: fuselage, wings, empennages (commercial & military aviation) | Excellent strength-to-stiffness ratio |

| T1100G | Military drones, eVTOL, mission-critical parts | Very high mechanical strength and impact resistance |

Learn more about intermediate carbon fibers

Toray’s T1100G fiber marks a new milestone in carbon fiber innovation. This next-generation fiber combines rigidity with excellent mechanical resistance. Made in France since the second quarter of 2025, this T1100G fiber enriches Toray Carbon Fibers Europe’s range of carbon fibers tailored for the aerospace industry.

Certified Expertise to Meet the Requirements of the Aeronautics Sector

Our carbon fiber manufacturing processes are certified to meet the highest international standards, including NADCAP accreditation (National Aerospace and Defense Contractors Accreditation Program) in Non-Metallic Materials Manufacturing. This ensures:

- Full control over specialized processes (carbonization, heat treatment, quality control; etc.)

- Complete traceability from raw material to finished product

- Proven reproducibility for long-term, highly critical programs

We also assist our customers in the material qualification process to streamline their development cycles.

Carbon fiber drone delivering a package

A Fully Integrated Value Chain: from Fiber to Finished Product

The competitiveness of an aeronautical project is not only based on the materials, but on the entire value chain. Toray offers a vertically integrated ecosystem that supports customers from start to finish: from design, fiber production and processing, to supplying semi-finished and finished products.

Our specialized sister companies, Toray Advanced Composites and Composite Materials America, also play key roles at every stage of the supply chain, guaranteeing quality, traceability, and responsiveness.

This vertical integration enables us to provide seamless industrial continuity, which is critical to the success of the most demanding aerospace programs.

Tailored Solutions for Industry Giants and Innovators

While Toray Carbon Fibers Europe has historically been a partner of major manufacturers like Airbus and Boeing, we are also committed to supporting the pioneers of tomorrow:

- Civilian UAV and drone developers seeking lightweight, long-range solutions

- Military drone designers focused on high performance

- eVTOL and flying taxi manufacturers shaping the future of urban air mobility

- Engine makers pushing the boundaries of propulsion

Our carbon fibers and composites also play a key role in space exploration missions. NASA’s Perseverance rover, now on Mars, features Toray composites in mission-critical parts such as its heat shield, rotor blades, and the Ingenuity drone chassis. A testament to the strength, lightness and performance of our materials.

Since the 1980s, Toray has been shaping aerospace innovation. With a focus on performance, a long-term industrial vision, and a deep commitment to R&D, we continue to empower the most ambitious projects in aviation.

Contact Toray Carbon Fibers Europe’s teams today for a technical consultation or quote.

Contact Toray Carbon Fibers Europe