Durability. Rigidity. Lightness

Torayca® Carbon Fibers

Since 1971, Torayca® carbon fiber has achieved worldwide recognition for its outstanding quality, reliability and performance. Over the years, Torayca® has become the first choice of engineers and manufacturers around the world. Regardless of industry or application, Torayca® carbon fiber is THE reference.

Torayca® Carbon Fibers Categories

The wide range of Torayca® carbon fibers, with various mechanical and sizing characteristics, has been developed to offer a solution adapted to each of your projects.

Torayca® carbon fibers are divided into two distinct categories:

T-Series

T-Series, referring to “Tensile strength”, is characterised by high tensile strength and a standard to intermediate modulus.

The number following the letter T indicates the approximate tensile strength in kgf/mm² or Ksi. For example, the T700S has a tensile strength of 711 Ksi.

M-Series

M-Series, referring to “Modulus”, is characterised by a high modulus.

The number following the letter M indicates the approximate tensile modulus in kgf/mm². For example, the M55J has a tensile modulus of 55 x 103 kgf/mm².

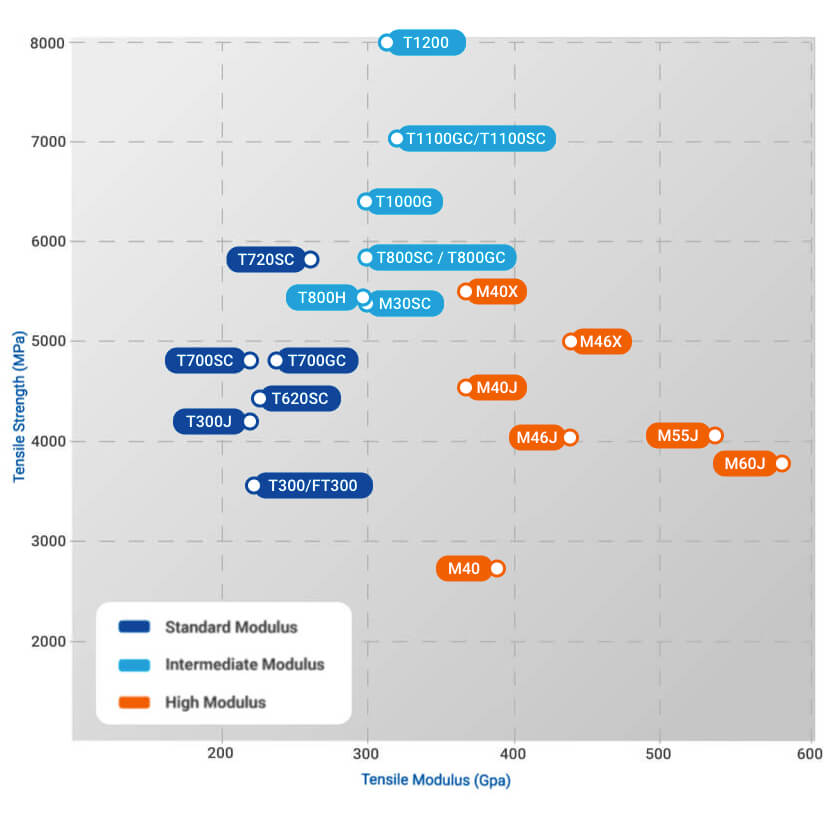

Toray provides a range of Torayca® carbon fibers classified by their tensile modulus:

- Standard modulus;

- Intermediate modulus;

- High modulus.

Standard Modulus (230-280 GPa)

T300/T300J

T300/T300J: The first fiber marketed by Toray Industries in 1971. It is a pioneer of the sky and space conquest. Forty years after its launch, the Torayca® technology used to produce the T300 remains unsurpassed.

Although initially intended for structural applications, the T300 is now mainly used as a laminate surface ply designed for aesthetic interior applications. The textile quality of the T300 is still unmatched. The alignment of the filaments, the consistency of the tow width and the sizing agent ratio of the T300 give a homogeneous finish to carbon laminates. These tows are available in 1K, 3K and 6K (Kilo per thousands of filaments) and are ideally suited for aesthetic applications.

T700S

At the heart of the Torayca® range, the T700S is the most renowned fiber in the composite industry. This Torayca® technology offers high mechanical performance and is perfectly adapted to large-scale industrial production, including compressed gas storage tanks (compressed natural gas, hydrogen, etc.).

The T700S is also the benchmark for other smaller markets such as marine applications, sports and leisure, civil engineering, etc.

The textile quality of the T700S is the reference for the carbon fiber industry. The alignment of the filaments, the tow’s cohesion and its ability to spread make it possible to obtain perfectly smooth laminates. The T700S is used in Class A laminates for automotive applications and surface ply for the sports and leisure market.

T700G

An Aerospace fiber offering higher tensile modulus and better fiber-matrix adhesion. It is particularly recommended for composite structures under transverse mechanical stresses.

Widely used in Aeronautics, the T700G can also be used in industrial applications.

T720S

The newest addition to the range, the T720S, with its superior mechanical properties to the T700S, is particularly suitable for pressure vessels where weight is a critical factor (especially hydrogen). Developed to meet the automotive industry’s requirements, the T720S is increasingly used by other industries to create lightweight and resistant products.

Intermediate Modulus (280 – 340 GPa)

T800H

The first Torayca® intermediate modulus fiber to be developeds, the T800H is used in prestigious Aerospace Engineering programmes. The T800H is the winning choice for Formula 1 and ocean racing.

T800S

a second-generation fiber, combining intermediate modulus fiber characteristics with industrial-scale usage. The T800S is the fiber of primary Aeronautical structures ‘par excellence’.

T1000G

Developed in 1986, the T1000G, with its long-unrivalled tensile strength, remains one of the flagship products of the Torayca® range.

T1100S

Top of the Torayca® range, the T1100S fiber represents a phenomenal technological leap. The T1100S provides the ideal solution for applications requiring both high tensile strength and modulus. This fiber is particularly suitable for manufacturing high-pressure tanks using the filament winding process.

T1100G

A fiber without compromise.

With its strength, tensile modulus and superior fiber-matrix adhesion, the T1100G is particularly recommended for composite structures under transverse mechanical stresses and is especially suitable for use in the aerospace industry.

High Modulus (>340 GPa)

Torayca® High Modulus (HM) fibers offer the highest carbon fiber modulus available on the market. PAN-based fibers are superior to pitch-based fibers due to their superior tensile and compressive strengths. Torayca® HM fibers are used for demanding applications in terms of rigidity and Coefficient of Thermal Expansion (CTE), such as rockets, high-end sports equipment and industrial rollers.

Toray Carbon Fibers Europe is the only carbon fiber manufacturer capable of producing high-modulus fibers on the European continent.

M40

This carbon fiber is intended for applications requiring a high modulus, but when tensile strength is of importance. It is mainly used for articulated arms in the robotics and electronics industries, where the rigidity of the mechanical arm ensures accuracy and precision.

M40J et M46J

These carbon fibers are intended for applications requiring both high tensile strength and modulus. Their preferred sectors are aerospace, F1 and ocean racing (for example, IMOCA Globe Series).

M55J et M60J

Exceptional carbon fibers, they are the only ones able to meet the dimensional stability requirements of Aerospace applications.

Surface and Sizing Treatments

Surface and sizing treatments are the final steps in the carbon fiber manufacturing process. These final steps are crucial to achieving the desired fiber-matrix adhesion level and the ability to be processed successfully.

The Torayca® range includes two types of surface treatments (standard and premium) combined with various sizing and suitable for the resin market. The types of surface and sizing treatments used are easily identifiable on the fiber’s reference code.

Example: A shipyard building boats and a manufacturer producing pressure vessels both use the T700S fiber. The shipyard uses a liquid infusion manufacturing process, while the tank manufacturer uses a filament winding process. Although they use the same fiber, different surface and sizing treatments are applied in order to fulfil their specific processing requirements.

The following table shows the different sizing treatments available and their characteristics.

| Sizing Code | Content to weight ratio (%) | Type | Resin Compatibility | Carbon Fibers |

| 1 | 0,5 | High Adhesion | Epoxy | T800S |

| 3 | 0,5 | High Adhesion Premium Surface Treatment |

Epoxy | T700G |

| 4 | 0,7-1 | Standard | Epoxy, Phenolic, BMI | FT300, T300J, T800H, T1000G |

| 5 | 1 | Standard | Epoxy, Polyester, Phenolic, BMI, Polyamide | T700S, T620S, T720S, T800H, T1100S, Gamme MJ |

| 6 | 0,3 | Low Content | Polyester, Polyamide | T700S, T620S |

| 7 | 0,6 | High Adhesion High Stability Premium Surface Treatment |

Epoxy | T1100G |

| F | 0,7 | Especially Compatible Vinylester | Vinylester, Epoxy | T700S |

WARNING

Our carbon fibers and composite materials are controlled products. Exporting these products outside the European Union requires an export license issued by your country’s relevant authorities. Your products manufactured using our carbon fibers and composites may also be subject to export control regulations.

For more information, consult the European regulations in force.